In dental implant surgery, ensuring precision and efficiency is key to a successful outcome. To facilitate smooth surgery and achieve optimal results, carefully selecting the right surgical tools is essential. Among these tools, the dental implant screwdriver plays a crucial role in the entire procedure. This article provides a comprehensive guide to help you choose the most suitable dental implant screwdriver for your practice, significantly improving surgical efficiency and enhancing patient satisfaction.

By thoroughly understanding the various models, materials, design features, and applications of dental implant screwdrivers, you can make a more precise selection based on the specific needs of the surgery, the patient’s individual conditions, and the practical considerations of your clinic. This not only ensures the smoothness and precision of the procedure but also helps shorten surgery time, reduce the patient’s treatment burden, and improve overall treatment outcomes and patient experience. Therefore, mastering how to choose the most suitable dental implant screwdriver is not only crucial for enhancing professional skills but also a key step toward achieving success and excellence in dental implant surgery.

螺丝刀-7205400100.webp)

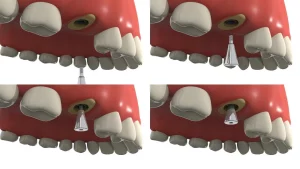

Types of Screwdrivers and Selection Criteria

In dental implant surgery, choosing the right screwdriver is critical for both the efficiency and safety of the procedure. The screwdriver affects not only the smooth execution of the surgery but also plays a vital role in ensuring patient safety and surgical quality. This section will explore the different types of screwdrivers, including manual screwdrivers, machine-driven screwdrivers, and integrated screwdrivers, their characteristics, and the recommended size and platform compatibility for each type to help you make a more precise match and improve surgical efficiency.

Manual Screwdriver vs. Machine-Driven Screwdriver

Manual Screwdriver:

- Features: Suitable for delicate operations, offering precise control over positioning and torque.

- Advantages: Manual screwdrivers provide high flexibility and precision, especially when adjusting screws in tight spaces.

- Applicable Scenarios: Ideal for surgeries requiring fine adjustments, such as complex implant or restoration procedures.

Machine-Driven Screwdriver:

- Features: Powered by a dental handpiece, it offers speed and high efficiency.

- Advantages: Machine-driven screwdrivers can insert screws quickly and steadily, making them ideal for routine or repetitive procedures.

- Applicable Scenarios: Suitable for surgeries that require high speed and efficiency, such as bulk implants or standard restorations.

Integrated Screwdriver

- Features: Combines screw holder and screwdriver in one tool for easy storage and use.

- Benefits: Enhances operational efficiency and reduces the risk of losing or contaminating screws.

- Applicable Scenarios: Especially useful in complex prosthetic restoration procedures, ensuring a smooth workflow.

- Size Selection: Precise matching for flexible operation.

Length and Size Selection

The length and size of the screwdriver directly affect its flexibility and adaptability to different surgical scenarios. Here are the common sizes and their applicable situations:

- 17mm Screwdriver: Ideal for smaller or narrower surgical areas, providing precise control.

- 22mm Screwdriver: Standard length, suitable for most implant surgeries, balancing flexibility with operational range.

- 28mm Screwdriver: Used for deeper or more complex surgical locations, providing greater extension and flexibility.

Platform Compatibility

Depending on the implant system platform, screwdrivers come in two types: NP (Narrow Platform) and RP (Regular Platform).

- NP (Narrow Platform): Suitable for smaller implants, ensuring screw stability.

- RP (Regular Platform): Suitable for standard-sized implants, ensuring the smooth progression of the surgery.

Choosing the correct screwdriver platform type ensures a tight fit between the screw and implant, reducing surgical risks and enhancing the overall outcome.

Screwdriver Design and Material

Since the screwdriver is a vital instrument in dental implant surgery, its construction and design are crucial. They have a direct influence on the accuracy of the surgery and the patient experience in addition to the longevity and security of the surgical tools. A well-chosen screwdriver design and material may provide robust support and seamless surgical execution, enabling physicians to continue performing at their best for extended operations.

Material Selection: Durability and Corrosion Resistance

The most well-known materials for screwdrivers are titanium alloy and medical-grade stainless steel because of their remarkable endurance and resistance to corrosion. In intricate surgical settings, the screwdriver will stay steady and long-lasting thanks to medical-grade stainless steel, which is renowned for its exceptional strength and resistance to wear. Titanium alloy provides a more durable and lightweight screwdriver due to its high strength, low weight, and resistance to corrosion. The selection of these two materials not only increases the screwdriver’s robustness but also successfully reduces the possibility of breakage or damage during the operation, guaranteeing the surgery’s safety.

Ergonomic Design: The Perfect Balance of Comfort and Precision

The screwdriver’s ergonomic form is essential for increasing user comfort and accuracy. A well-designed handle greatly reduces hand strain during lengthy operations by improving grip and accommodating the hand’s natural curves. This design improves the operation’s natural feel and fluidity, which increases surgical accuracy. Consequently, it helps make the patient’s experience receiving therapy safer and more effective.

Efficiency and Maintenance of Screwdrivers

The screwdriver’s design affects not just accuracy and safety during dental implant surgery, but also the procedure’s efficiency and smoothness. A well-designed screwdriver should provide stability and durability under high-intensity situations, improve operating efficiency, and simplify surgical procedures.

Operational Efficiency: Smooth Workflow and Integration

By eliminating pointless stages, the screwdriver’s design should simplify surgical processes. The continuity and effectiveness of operations may be greatly increased by using screwdrivers that easily interface with other essential tools, such as dental handpieces. In the end, this increases overall surgical efficiency by reducing disruptions and corrections and enabling a more fluid and natural operation.

Maintenance: Long-Term Performance, Cleaning, and Disinfection

For screwdrivers to last a long time and operate consistently, proper maintenance is essential. Tools used in high-frequency surgical settings are susceptible to filth, germs, or residue accumulation, which may have a detrimental impact on results. The screwdriver must be thoroughly cleaned and sterilised on a regular basis to avoid cross-contamination and guarantee dependable operation in subsequent processes.

In addition to extending their lifetime, well-maintained screwdrivers guarantee peak performance throughout each procedure, improving accuracy and safety and giving patients a more reliable and effective medical experience.

Selecting the Right Screwdriver for Your Practice

Selecting the appropriate screwdriver is essential for increasing surgical effectiveness, guaranteeing success rates, and providing patients with the best treatment possible. Dental offices may more successfully accomplish their operational objectives by matching screwdriver kinds and specifications to the particular requirements of the clinic, surgical techniques, and practitioner preferences.

Clinic Requirements and Procedure Types: Important Things to Think About

- Intricate Restorative Procedures: Integrated screwdrivers are perfect for clinics that deal with complicated restorative situations. They are ideal for complex procedures because of their all-in-one design, which increases efficiency and lowers the possibility of tool loss or contamination.

- Procedures for general implants: Standard-length, machine-driven screwdrivers are more efficient for common implant procedures because they allow for steady and rapid screw insertion, which shortens process times.

Tool Performance: Sturdiness, Compatibility, and Ergonomics

When choosing a screwdriver, take into account:

- Durability: Stable, long-term tool performance is guaranteed by premium materials and workmanship. Tools that have undergone extensive reliability testing may reduce the possibility of breaking while performing processes.

- Ergonomics: Well-made handles increase comfort and surgical accuracy, improve grip, and lessen hand fatigue during prolonged procedures.

- Compatibility: By cutting down on adjustment time and streamlining processes, screwdrivers that smoothly integrate with dental equipment (such as handpieces) improve surgical efficiency.

Gain Knowledge from Others: Evaluations and Suggestions

Ask other dentists for their opinions on screwdriver models and brands. Gaining insight from their experiences may help you evaluate the tools’ usefulness and drawbacks, allowing you to make better judgements.

Dental offices may provide safer and more effective treatment while increasing operational efficiency and success rates by using the appropriate tools. To make sure the screwdriver satisfies the demands of your clinic, assess your needs, take performance criteria into account, and depend on peer recommendations.

Conclusion

The screwdriver is an essential instrument used in dental implant procedures. An appropriate screwdriver lowers procedural risks while improving accuracy, productivity, and safety. By being aware of screwdriver kinds, materials, designs, and maintenance methods, professionals may choose the best instruments for their operations, improving surgical quality and patient happiness.

Key Points:

- Materials: Titanium alloy and medical-grade stainless steel provide longevity and resistance to corrosion, offering a strong basis for successful surgery.

- Design: Screwdrivers are dependable surgical helpers because to their ergonomic grips and smooth integration, which improve comfort and operational efficiency.

- Usage Techniques: To achieve optimum performance and lifespan, familiarity with the tool’s capabilities, usage, and maintenance is essential.

Purchasing top-notch screwdriver models and brands lays a solid basis for dental implant treatment success. It guarantees safer, more effective, and patient-friendly therapies in addition to improving accuracy and efficiency. Make screwdriver selection and use a top priority in day-to-day operations to optimise its impact on surgical results.