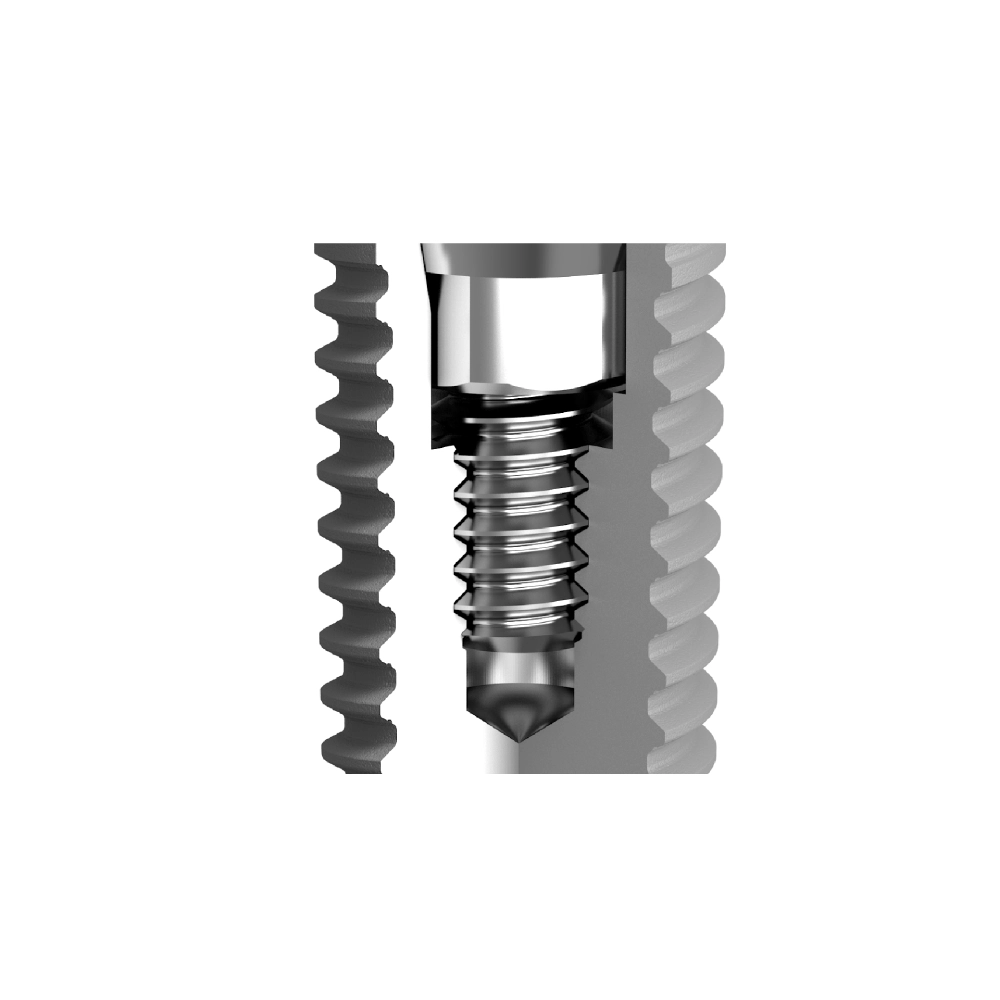

The DMEqual implant features an internal hexagonal conical connection design that offers a more versatile approach to abutment restoration, catering to various clinical needs. Its internal conical connection effectively reduces the risk of inflammation, ensuring better long-term stability. The conical apex design allows for secure fixation in double cortical bone, while the four-blade self-tapping groove demonstrates excellent self-tapping performance in cases of insufficient preparation. Coupled with SLA surface treatment and groove design, this enhances the implant’s initial stability and biocompatibility, making it an ideal choice for your needs.

Faster implantation and optimized surgical experience

Abutment prosthetics are more diversified with hexagonal interlocking to reduce inflammation effectively

Double cortical bones fixation is permitted with the tapered root tip Four-edged tapping grooves have good tapping effect when the width or the length of the hole are insufficient

Tight protective layer is formed with soft tissue attachment

Flexible for a wide range of bones

Increase the contact area and stability

Effectively reduces bone resorption around the implant and forms a stable soft tissue closure

Nos implants sont fabriqués en titane de haute qualité, selon des procédés de fabrication avancés, et sont garantis à vie.

The DMEqual implant features a 12° tapered connection that effectively disperses stress and provides a tight seal to prevent bacterial growth. Its excellent load distribution and sealing properties ensure stability and safety during use. The internal hexagonal connection enhances anti-rotation capability, while the hexagonal lock design allows for versatile restoration directions. Additionally, the tapered connection reduces inflammation risk, offering patients a more comfortable experience and improved treatment outcomes.

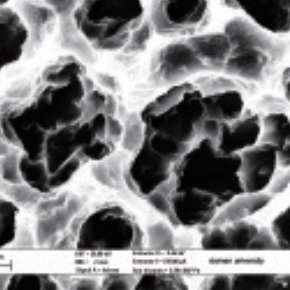

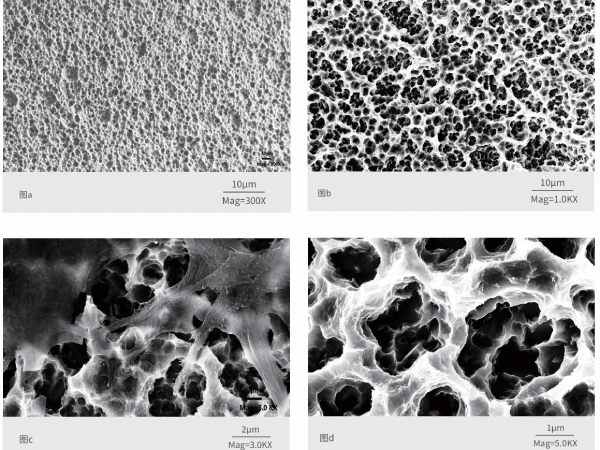

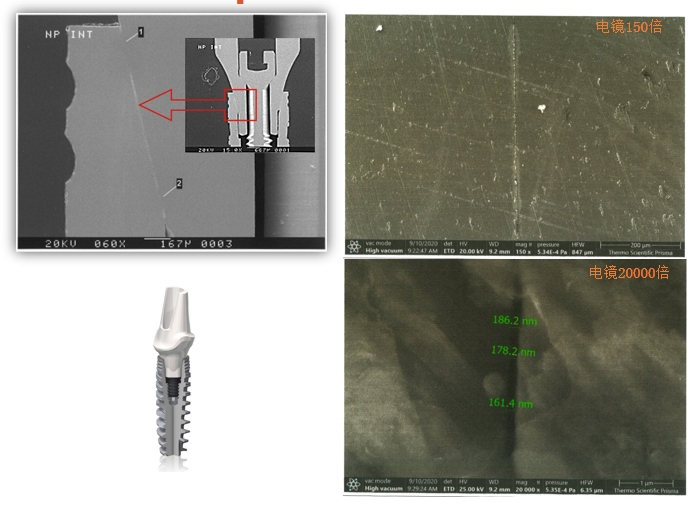

The DMEqual implant features a surface treatment that uses mixed particle size sandblasting to create a unique, uniformly structured micro-level morphology with deep pores, enhancing the contact area with bone tissue. This multi-level micro surface undergoes high-temperature activation, resulting in a thin, crystalline titanium dioxide layer that significantly reduces the contact angle and promotes biomineralization post-implantation. This treatment facilitates both short-term loading and long-term osseointegration, ensuring a successful and stable implant experience.

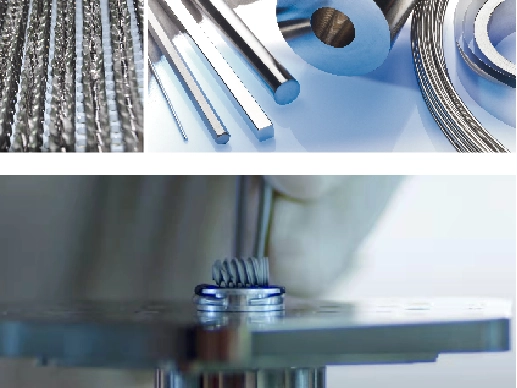

Our implants are made from high-quality Cold Working Titanium Grade 4. This material is produced by cold-working Grade 4 pure titanium, a process that not only retains the biocompatibility of pure titanium but also significantly enhances its mechanical strength. With exceptional biocompatibility, it integrates well with surrounding tissues in the body without causing adverse reactions. Additionally, its high strength allows the implant to withstand greater bite forces, making it particularly suitable for dental restorations that need to endure heavy chewing pressure.

Au microscope électronique 150x et 20000x, l'écart entre le DentalMaster et le pilier est inférieur à 0,2micron,plus bas que les produits similaires dans l'industrie, ce qui montre que la précision de traitement est plus élevée, donc que l'anti-fatigue est meilleure, que l'anti-déformation est meilleure, que la durée de vie est plus longue.

Nous invitons les distributeurs, les hôpitaux et les cliniques dentaires à nous rejoindre pour créer plus de sourires, alimentés par une passion commune pour les implants dentaires.

DentalMaster est une société spécialisée dans l'implantation dentaire. Les marques telles que Nobel Biocare, Short Bicon, Straumann, Zimmer, Megagen, Dentium et Hiossen sont des marques déposées de leurs sociétés respectives. DentalMaster n'a aucune affiliation commerciale avec ces sociétés. La mention de ces marques a pour seul but d'identifier avec précision les implants, instruments, piliers et composants compatibles proposés par DentalMaster.

Copyright © 2024 Dental Master CE / ISO13485. Tous droits réservés.