In today’s dental field, internal hex implant connection technology has undoubtedly risen to the forefront of the market, becoming the preferred choice among many dental experts, significantly surpassing its traditional predecessor—the external hex connection. This revolutionary design was created to precisely address and effectively mitigate the clinical challenges and complications that may arise with external hex connections, marking a significant leap in implant connection technology. It is now widely regarded as the “gold standard” in the field.

Some implant brands compatible with internal hex connections include Alpha Bio Tec.®, Legacy™ by Implant Direct®, BioHorizons®, Zimmer®, Blue Sky Bio®, Lamina™ by Edison Medical™, Adin®, and Noris Medical®, Dental Master®.

The Migration from External Hex to Internal Hex Implants

From the pioneering era of external hex connections to the revolutionary age of internal hex technology, dental implant technology has undergone a profound transformation. This shift began with the external hex connection system developed by the renowned Swedish orthopedic surgeon Per-Ingvar Brånemark. As a trailblazer in modern implant technology, this system has left an indelible mark on dental history.

External hex implants can experience the phenomenon of external-to-internal migration due to inherent limitations of the external hex design, such as high risks of fatigue fractures and frequent screw loosening. To achieve a low-profile design within the oral cavity, the dimensions of the external hex must compromise on the ideal joining height between the implant and abutment, leading to insufficient surface contact and subsequent mechanical complications.

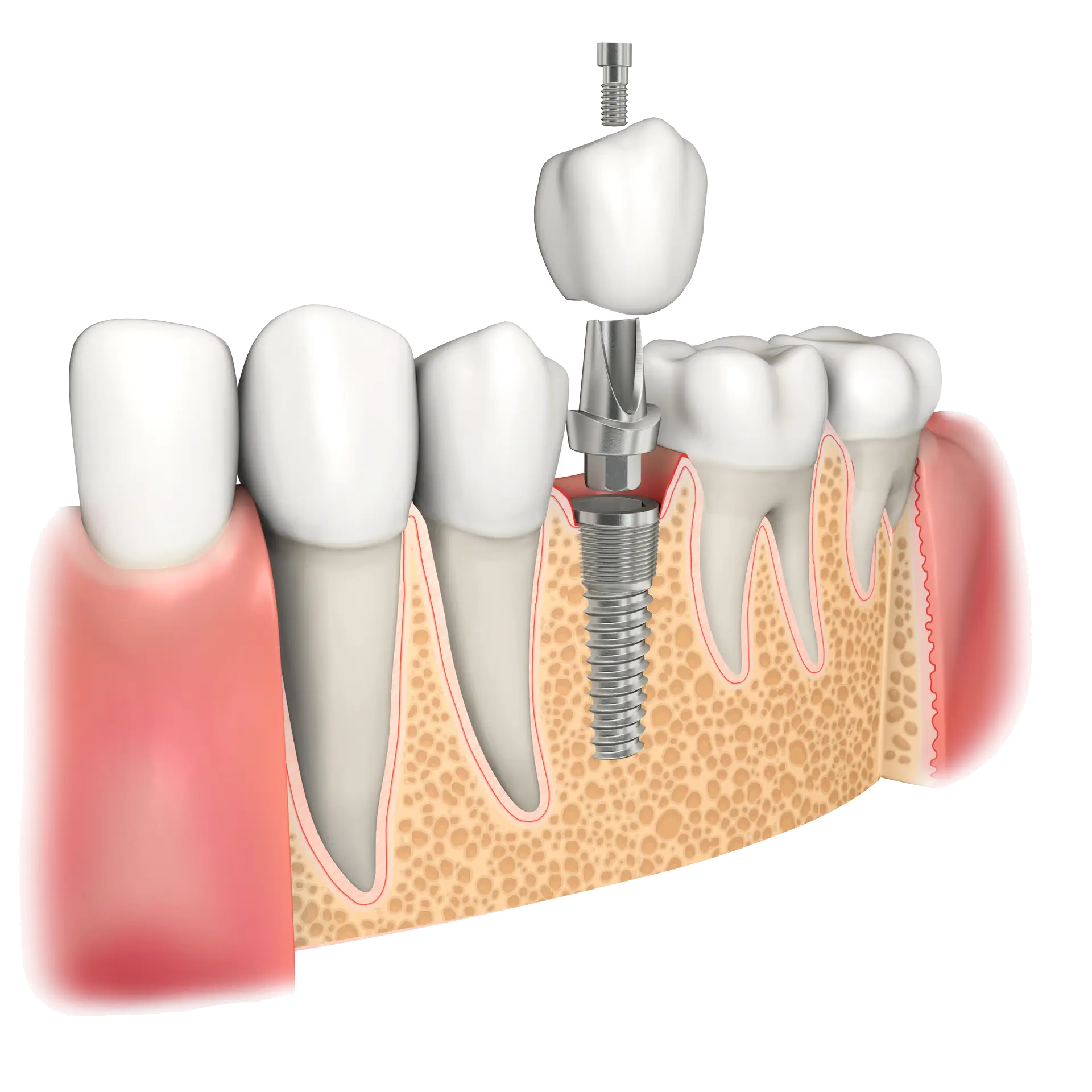

In this context, the internal hex connection technology emerged as a revolutionary solution. By embedding the hexagonal structure within the implant, this innovative design significantly enhances the system’s stability against lateral forces, effectively reduces micro-movement, and greatly lowers the risk of microscopic expansion from long-term use. The internal hex design conceals the connection components within the implant, thereby dispersing and reducing the direct stress impact on the prosthesis, which improves both stress stability and the stability of the implant screws.

Data comparisons illustrate the success of this transformation: compared to the 54% screw loosening rate of external hex connections, the internal hex connection system’s screw loosening rate drops dramatically to about 6%, providing a much more solid foundation for long-term implant success. Additionally, the internal hex design enhances aesthetics by lowering the height of the platform and prosthesis, allowing the implant to sit more naturally along the gum line and offering patients a more aesthetically pleasing result.

Other Internal Connections Beyond Internal Hex

While internal hex implants have undoubtedly become a widely adopted standard in the field of dentistry, they are not the only option available. Exploring the diversity of internal connections reveals several alternatives, each with its unique features.

Tri-Lobe Connection: The tri-lobe connection stands out with its distinct three-lobed design, which simplifies the seating of the abutment. Although this design is somewhat limited in choice, it follows the planar contact pattern seen in external hex designs but optimizes internal space for easier abutment placement. However, unlike conical connections, the tri-lobe design lacks the tapered shape, which, while enhancing rigidity and stability, demands a higher level of technical skill from dentists. Improper placement can lead to gaps that pose risks of bacterial invasion and infection.

Conical Connection: An increasingly prominent alternative is the conical connection, which is showing potential to become a leading choice in the industry. The conical connection’s primary advantage lies in its unique tapering effect. When the abutment is twisted into place, the phenomenon of cold welding between the implant and abutment effectively reduces gaps, thereby minimizing the formation of micro-gaps. In contrast, while internal hex connections are stable and reliable, they can sometimes face issues with gaps if the implant is not fully seated.

Analyzing the potential weaknesses of internal hex connections and the advantages of conical connections is crucial for advancing dental implant technology. The conical connection, with its innovative design and outstanding performance, is poised to become a leading technology in implant connections in the future.

Comparison of Internal Hex Implant Systems with Other Connection Types

Internal hex implant systems are often favored for their superior stability, fatigue resistance, and operational convenience. Their design features a larger contact area, enhancing the connection depth and overall stability of the system. Additionally, internal hex connections generally exhibit better fatigue resistance compared to external connections. They are less prone to failure under lateral loads, with issues typically arising at the abutment and screw interface rather than the implant itself, facilitating easier repairs. However, despite their advantages, internal hex implants can still experience slight micro-movement at the connection interface, which may lead to micro-gap formation and potential microbial leakage over time. They are also known for their good biocompatibility, which helps in reducing inflammation and bone resorption around the implant.

Conical Connections: A Solution to Micro-Movement

The latest advancement in platform interfaces is the conical connection, characterized by its unique cone-shaped geometry, which maximizes stability. Unlike internal hex designs, the conical connection reduces the surface area of the interface, allowing for a tighter and more secure fit between the abutment and the implant. This design facilitates a cold welding effect when the system is installed, which enhances stability by locking the abutment and implant together, effectively eliminating screw loosening and micro-movement. The conical shape promotes even stress distribution on the restoration under load. Compared to internal hex connections, conical connections offer undeniable advantages in stability and performance, without additional costs.

Future Trends in Implant Connection Development

As we explore the future trends in implant connection technologies, it becomes clear that while internal hex implant systems have established a significant presence in the market due to their unique advantages, their dominance is increasingly being challenged by conical connection systems. Conical connections are emerging as a formidable force, showcasing their potential to lead innovations in dental implant technology.

Looking ahead, conical connections are likely to become the preferred choice in the field of dental implants. This shift is driven by the conical connection’s remarkable advantages in providing superior stability and significantly reducing the risk of complications. The design principle of conical connections not only enhances the locking effect between the implant and abutment but also optimizes stress distribution, ensuring long-term stability and reliability.

With the rapid advancements in dental technology, there is a growing demand for efficient, convenient, and adaptable solutions. Conical connection systems, with their feature of not requiring complex technical conversions or special tools, perfectly align with this demand trend. This suggests that, in the near future, as market acceptance increases and technology continues to mature, conical connection systems are poised to dominate the implant connection market.

Although this transformation may be gradual, the advantages presented by conical connection systems are likely to secure a larger market share and drive the dental implant field toward more efficient, safe, and convenient solutions. Therefore, we have reason to believe that conical connections will soon become the mainstream choice in implant connection technology, leading a new wave of advancements in dental implant technology.