Screw System Type: Tenting Screws For Bone Grafting

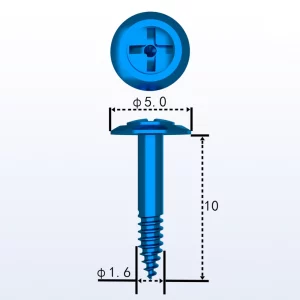

Screw Head Diameter: 5 mm

Material: Made of FDA-approved Titanium

Diameter: 1.6 mm

Length: 7 mm / 10 mm

Application: Used when vertical/horizontal to GBR is required

The tenting screws for bone grafting feature a unique locking cone-shaped cross-drive system that makes the pickup and transportation of screws exceptionally simple and secure. This design ensures that the screws are accurately delivered to the surgical site, providing strong support for the smooth progress of the operation. The tip and thread design of the screws easily penetrate bone tissue, while the precision threads create a tight bond with the bone, eliminating the need for pre-drilled guide holes. This capability allows for precise placement even in hard cortical bone, simplifying surgical steps and significantly enhancing precision and efficiency.

The screw head diameter of the tent screw is 5mm, offering a broad surface area. This design not only enhances the stability and fixation of the screws but also effectively prevents risks such as membrane perforation or tearing during the surgical procedure, further ensuring patient safety.

| Nr części. | D(mm) | H(mm) |

|

7018316072 1.6 7 |

||

|

7018316102 1.6 10 |

||

DentalMaster jest firmą specjalizującą się w stomatologii implantologicznej. Marki takie jak Nobel Biocare, Short Bicon, Straumann, Zimmer, Megagen, Dentium i Hiossen są zastrzeżonymi znakami towarowymi odpowiednich firm. DentalMaster nie ma żadnych powiązań handlowych z tymi firmami. Wymienienie tych marek ma na celu wyłącznie dokładną identyfikację kompatybilnych implantów, instrumentów, łączników i komponentów oferowanych przez DentalMaster.

Copyright © 2024 Dental Master CE / ISO13485. Wszelkie prawa zastrzeżone.