In the complex and precise field of surgical procedures, selecting the right implant is of paramount importance. As commonly used internal fixation devices, bone pins and bone screws play vital roles in orthopedic surgeries. Although they may appear similar, they exhibit significant differences in structural design, mechanical performance, and application scenarios. In particular, during bone grafting procedures, bone grafting screws have become the ideal choice for achieving maximum stability and long-term durability, thanks to their exceptional fixation capabilities.

This article will explore the key differences between bone pins and bone screws in depth, with a special focus on the advantages and characteristics of bone grafting screws in clinical applications, providing medical professionals with valuable insights for selecting the appropriate surgical instruments.

What is a Bone Tack?

As a small, specialized fixation device, the bone tack plays a vital role in the field of surgery. Its primary function is to securely anchor membranes, grafts, or soft tissues to bone structures with precision. Compared to traditional screws, bone tacks are notably shorter, which allows for quick and efficient placement during surgical procedures. The use of a dedicated applicator further enhances the accuracy and convenience of bone tack insertion.

In clinical applications such as guided bone regeneration (GBR) and soft tissue fixation, bone tacks provide reliable stability, contributing significantly to the success of surgical outcomes. Their application is extensive, particularly in dental, craniofacial, and orthopedic surgeries, where they serve an irreplaceable role.

From a material perspective, bone tacks are typically made from biocompatible materials such as titanium. This choice is intentional, as titanium offers excellent strength to withstand the mechanical forces at the surgical site. It also ensures outstanding stability, keeping the tack securely in place over time. Most importantly, titanium’s superior biocompatibility allows it to remain safely in the body long-term without causing adverse reactions, thereby safeguarding patient health and safety.

What is a bone screw?

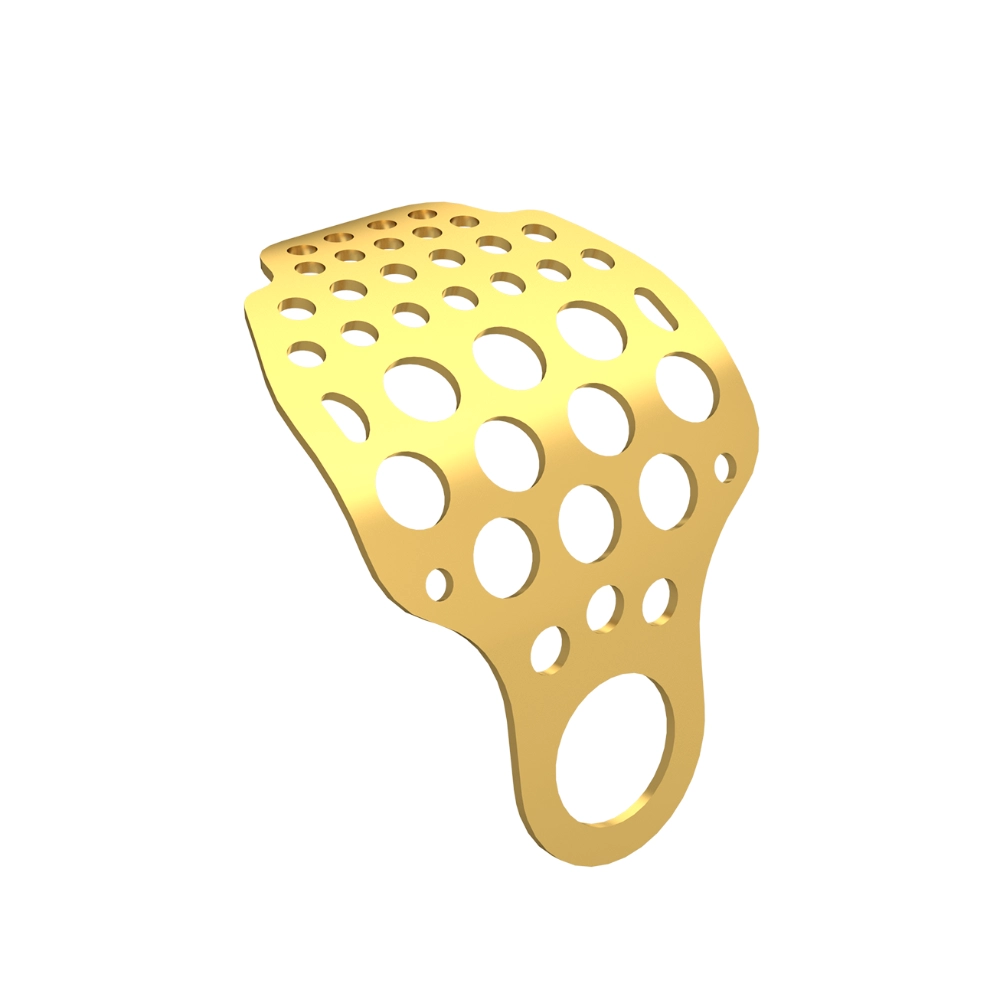

A bone screw is a specialized orthopedic implant designed to provide firm and stable fixation of bones or bone grafts during surgical procedures. Unlike bone tacks, bone screws are typically longer and feature threaded shafts that allow them to engage securely with bone tissue, delivering maximum mechanical strength and long-term stability. Their robust design makes them ideal for demanding surgical applications, such as securing bone plates, meshes, or bone blocks.

Bone screws play an essential role in a wide range of surgeries, including orthopedic, dental, and craniofacial procedures. They are especially critical in bone grafting surgeries, where strong and durable fixation is required to promote proper healing and integration of the graft material with the natural bone.

Manufactured from high-quality, biocompatible materials like titanium, bone screws are built to withstand the mechanical stresses of the human body while ensuring excellent biocompatibility. Titanium’s natural corrosion resistance and tissue-friendly properties make it a safe, long-term solution for internal fixation, minimizing the risk of adverse reactions and providing reliable support throughout the healing process.

Comparison Between Bone Screws and Bone Tacks

| Aspect | Bone Screws | Bone Tacks |

|---|---|---|

| Primary Use | Fixation of bone grafts, providing long-term stability | Quick fixation of barrier membranes for guided bone regeneration (GBR) |

| Typical Application | Bone defect repair, ridge augmentation, securing bone blocks | Membrane stabilization during GBR to maintain graft position |

| Structural Features | Longer, threaded design for deep bone anchorage | Short, tack-shaped, non-threaded for fast placement |

| Placement Method | Requires pre-drilling and gradual insertion with screwdriver | Inserted quickly using a dedicated applicator tool |

| Stability | High mechanical strength for load-bearing and lasting fixation | Provides initial stability for non-load-bearing membranes or soft tissues |

| Material | Medical-grade titanium or titanium alloy | Medical-grade titanium or titanium alloy |

| Biocompatibility & Safety | Excellent biocompatibility, suitable for long-term implantation | High biocompatibility, typically used for temporary fixation |

| Surgical Efficiency | Takes longer due to drilling and threading process | Faster placement, improves surgical efficiency |

How Are Dental Bone Screws Installed?

Dental bone screws are installed through a precise and controlled surgical procedure designed to ensure optimal fixation of bone grafts or blocks. The process begins with careful treatment planning and the selection of the appropriate screw size based on the defect and graft dimensions. Once the surgical site is prepared, a pilot hole is typically drilled into the bone to guide the screw placement and prevent unwanted bone fractures.

Using a surgical driver or a dedicated insertion tool, the bone screw is then carefully inserted into the pilot hole, securing the graft or bone block firmly in place. Throughout the procedure, the surgeon ensures proper alignment and depth to achieve maximum stability without compromising surrounding anatomical structures. Thanks to their threaded design and biocompatible material, dental bone screws provide strong, long-term fixation, supporting effective bone regeneration and successful implant outcomes.

The Best Instruments for Bone Screws and Bone Tacks

In the demanding field of dental and orthopedic surgery, the precision and efficiency of surgical instruments play a critical role in achieving successful outcomes. Choosing the right toolkit not only enhances surgical accuracy but also improves workflow and patient safety. Here, we explore two essential categories of instruments: those designed for bone screws and those specialized for bone tacks, with a focus on their advanced features and practical advantages.

DentalMaster Bone Fixation Screw Kit

The DentalMaster Bone Fixation Screw Kit is meticulously designed to meet the diverse needs of dental bone fixation procedures. This comprehensive kit includes a variety of bone screws, screwdrivers, drivers, drills, and other essential surgical tools. Each tool in the kit undergoes strict quality control and sterilization to ensure the highest standards of safety and sterility throughout the surgical process.

One of the standout features of this kit is its thoughtful layered design, which organizes tools and bone screws in clearly defined sections. This classification allows surgeons to quickly and easily access the instruments they need, reducing preparation time and enhancing surgical efficiency. With this level of organization and precision, the DentalMaster Bone Fixation Screw Kit is an invaluable asset for professionals aiming to deliver reliable and effective results in bone fixation surgeries.

Bone Tack Solutions

Bone tacks are crucial for securing membranes and soft tissue grafts during surgical procedures. To meet varying clinical requirements, two advanced bone tack kits are available: the Automatic Bone Tack Kit and the Bone Tack Tapping Surgical Kit.

Automatic Bone Tack Kit

The Automatic Bone Tack Kit is engineered for speed and convenience. Featuring a one-click implantation mechanism, this kit allows for rapid and efficient tack placement, minimizing surgical time while maintaining precision. Crafted from high-quality titanium, the tacks offer excellent biocompatibility and durability.

Key features of the Automatic Bone Tack Kit include:

- Titanium bone tacks for superior strength and biocompatibility

- Positioner with a capacity of 36 tacks for extended procedures

- One-click implantation for efficient and quick use

- Ergonomic wave-pattern handle for a comfortable grip

- Available bone tack diameters: 2.0mm and 2.5mm

- Available bone tack lengths: 3mm, 4mm, and 5mm

- Wide, easy-to-pull tail cap for fast reload

- 155-degree curved design to reach difficult anatomical areas

Bone Tack Tapping Surgical Kit

For procedures requiring even greater control and versatility, the Bone Tack Tapping Surgical Kit provides a comprehensive selection of tools. This kit includes multiple types of nail holders to accommodate different surgical approaches, as well as precision instruments for implantation and removal of bone tacks.

The Bone Tack Tapping Surgical Kit includes:

- Nail holder (hook type)

- Nail holder (straight type)

- Nail holder (curved type)

- Extractor

- Long-type machine screwdriver

- Limit drill

- Short-type machine screwdriver

Both the Automatic Bone Tack Kit and the Bone Tack Tapping Surgical Kit are designed to provide reliable stability and ease of use in dental surgeries involving membranes and bone grafts.

Characteristics of Bone Tacks in Dental GBR (Guided Bone Regeneration) Surgery

- Design and Operational Advantages

- Compact and Flexible: Bone tacks are usually shorter and have a smaller diameter, allowing for more flexible operation in the confined space of the oral cavity. For instance, in procedures such as sinus lifts, where precise operations are required, bone tacks can more easily reach the target location without being restricted by surrounding anatomical structures, unlike longer bone screws.

- Quick Placement: Bone tacks are designed for rapid and efficient placement, typically with a dedicated applicator. Time is crucial in GBR surgeries, and quickly placing the bone tacks can reduce surgical time, minimizing the risk of infections and other complications. For example, during simpler alveolar bone augmentation surgeries, the surgeon can quickly implant bone tacks, thus gaining time for subsequent placement of the guide membrane and other operations.

- Fixation and Stability

- Surface Properties for Fixation: Some bone tacks have special surface treatments, such as rough or porous structures, which increase the contact area between the tack and the surrounding bone or soft tissue. This enhances fixation stability. In GBR surgeries, stable fixation is critical for maintaining the correct position of the guide membrane during healing, and the tack’s properties help prevent displacement of the membrane.

- Initial Stability: Bone tacks provide reliable initial stability for membranes, grafts, and other materials. During the early stages of bone regeneration, when new bone hasn’t yet reached sufficient strength, bone tacks ensure the guide membrane tightly adheres to the bone surface, creating a stable environment for bone cell growth and regeneration.

- Material Characteristics

- Good Biocompatibility: Bone tacks are typically made from biocompatible materials like titanium. Titanium offers excellent corrosion resistance in the oral environment and does not provoke adverse reactions with surrounding tissues, allowing it to remain safely in the body long-term. During the healing process of GBR surgery, bone tacks do not interfere with the normal repair and regeneration of surrounding tissues, ensuring a high success rate for the surgery.

Characteristics of Bone Screws in Dental GBR Surger

- Mechanical Performance Advantages

- High Strength Fixation: Bone screws generally have longer threads and larger diameters, providing greater fixation strength. In GBR surgeries that require resistance to higher occlusal forces or need long-term stability, such as bone augmentation around implants, bone screws offer better resistance to external forces, preventing grafts or guide membranes from loosening or shifting.

- Long-lasting Stability: Due to their structural design, bone screws form a closer bond with the bone once implanted, providing long-term stability. Throughout the bone regeneration process, bone screws continue to function effectively, ensuring the guide membrane and grafts remain in the correct position, promoting new bone formation and maturation.

- Wide Applicability

- Suitable for Different Bone Qualities: Bone screws come in various specifications and types, which can be selected according to the patient’s bone quality (such as bone density and strength). For patients with more porous bone, screws with special thread designs can be chosen to improve fixation reliability. This makes bone screws versatile and applicable in various complex GBR surgical scenarios.

- Used for Various Fixation Needs: In addition to securing guide membranes and grafts, bone screws can also be used to fix bone blocks, implants, and other materials. In GBR surgeries involving large bone grafts, bone screws can firmly secure the bone block in the defect area, facilitating the healing and integration of the graft.

- Operational Precision

- Self-Tapping or Pre-Tapping Design: Some bone screws are self-tapping, meaning they can directly engage with the bone tissue upon insertion, reducing the number of steps in the surgical process and saving time. Others require pre-tapping, which involves preparing the bone with a pre-drilled hole to improve precision during insertion. In GBR surgeries, accurate placement of the screws is critical to the success of the operation, and this design feature helps improve surgical quality and outcomes.

Conclusion

Although both bone tacks and bone screws serve as fixation devices in surgical procedures, they differ significantly in structure, performance, and application scenarios. Structurally, bone tacks are typically shorter and more compact, often equipped with specialized applicators for quick and precise placement. Bone screws, on the other hand, are generally longer with various thread designs, some featuring self-tapping or pre-tapping capabilities to accommodate different bone densities and fixation needs.

In terms of performance, bone tacks, with their small and flexible design, allow for efficient operation in confined spaces. Their specially treated surfaces enhance initial fixation stability. Bone screws, by contrast, excel in scenarios that require greater strength and long-term stability, especially when subjected to significant external forces.

For surgeons, a thorough understanding of the differences between bone tacks and bone screws is crucial. In clinical practice, the choice of the appropriate implant must be based on the patient’s specific condition, surgical site, bone quality, and procedural requirements. Only by making an accurate selection can the advantages of both bone tacks and bone screws be fully utilized, thereby improving surgical success rates and promoting patient recovery. Looking ahead, as medical technologies continue to evolve, the design and application of bone tacks and bone screws will keep advancing, offering more and better options for surgical procedures.